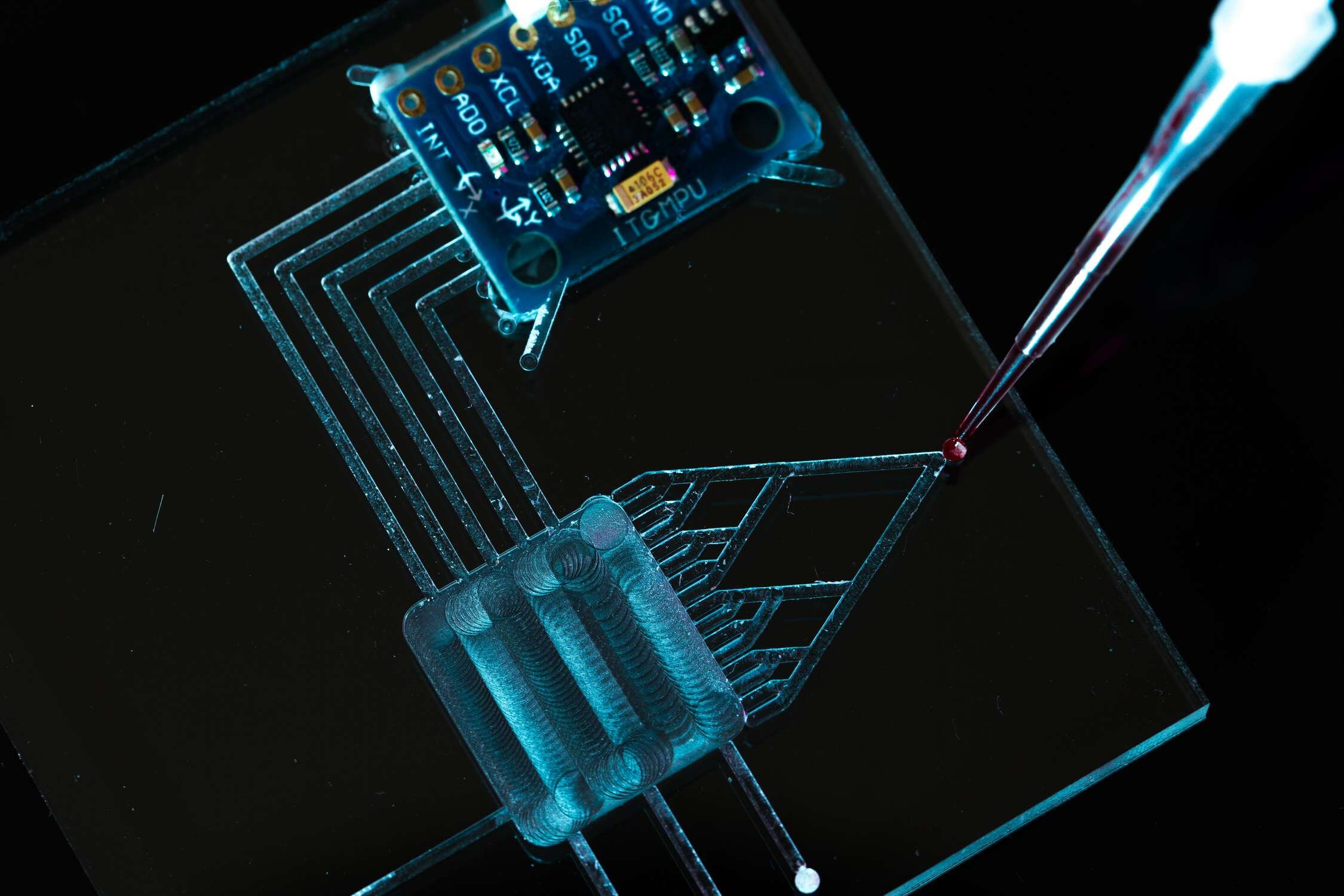

The small-and-mighty fabrication solution for microfluidics developers and disruptors.

At SU8 Masters, we know that high-quality, reliable tools are the critical first step developing game-changing products.

With over 20 years of experience in nanotechnology, MEMS, and microfluidic devices, we partner and problem-solve with each of our clients to ensure they get exactly what they need. Partnering with leading institutions and innovators, including research labs, medical device manufacturers, and technology firms, we ensure each SU8 project meets exacting standards of precision and functionality. Founded by industry veterans with a deep understanding of SU8 material properties and applications, SU8 Masters combines technical expertise with a commitment to innovation. And our quick turnarounds allow you to test your ideas while the light bulb is still warm. SU8 material can be the perfect solution for your needs.

WHAT WE DO

SU8 fabrication for every application

SU8 epoxy is a high-fidelity, biocompatible, negative photoresist material with an ever-growing range of innovative uses.

Microwell arrays

Cell separations

Cellular biophysics

Biomedical engineering

Micro Molding

Biodegradable implants

Telecommunications

Innovative Micro Technology

Micro gears, filters, and more.

MEMS & Medical Devices

Part fabrication

Thermo actuators

Optics

Microfluidic Applications

Cell sorting

Evolutionary biology

Droplet formation

Drug development

Microcontact printing

PDMS stamps for Soft Lithography

Embossed plastics

Surface chemistry

Cell biology

Micro replication

Engineered abrasives

Microneedles

Specialty wafers

Have a new or challenging SU8 project?

HOW WE WORK

On spec.

On time.

Our responsive team and small-batch approach guarantee high-integrity SU8 prototypes with little downtime.

Experienced review

Our SU8 Master team thoroughly reviews each project to help eliminate potential issues before we go into production.

Focused attention

Since we specialize in custom, small-batch prototype solutions, we know what to look for—and we pay attention to the details that matter.

Quick turnarounds on SU8 Orders

While we always prioritize quality over speed, our SU8 fabrication orders are delivered within 1-2 weeks of receiving the order. Expedited options available!

TESTIMONIALS

Every project, a partnership.

“You have no idea how much better you are than others I’ve worked with.”

“You know, you really could charge me more for this.”

“The change you just suggested probably saved us 3 months of development.”

Our simple process

makes it easy.

Step 1

Submit your design

Complete our form below and upload your design files.

Step 2

Confirm specs

We’ll deliver a quote based on the complexity of the SU8 master.

Step 3

Start production

We ship all SU8 masters quickly so you can get to work.

We guarantee to make it right.

Your satisfaction and long-term partnership are important to us. On the rare occasion we don’t make your SU8 master to your approved specifications, we’ll refabricate at our own expense. We want your SU8 product to be perfect.

-

SU-8 is a commonly used epoxy-based material in the creation of small-scale devices. It's popular in microfabrication processes because of its strong stability, durability, and ability to work well with different surfaces. Originally developed by IBM, SU-8 photoresist has impressive features, like high resolution and aspect ratio, making it ideal for building tiny mechanical and fluidic systems. It finds applications in various areas, from making tiny structures in sensors and actuators to crafting complex three-dimensional microfluidic pathways. Thanks to its excellent physical properties, stability against heat, and resistance to chemicals, SU-8 photoresist plays a crucial role in advancing microfabrication technology. It allows the development of intricate structures for different purposes, such as in biomedical devices, sensors, and microelectronics. The material's reliability and versatility make it essential in the world of small-scale engineering, contributing to ongoing research and technological progress. Its ease of processing and adaptability to various fabrication techniques, including photolithography and soft lithography, further solidify its role as a versatile material in research and industrial applications.